Descripción del producto

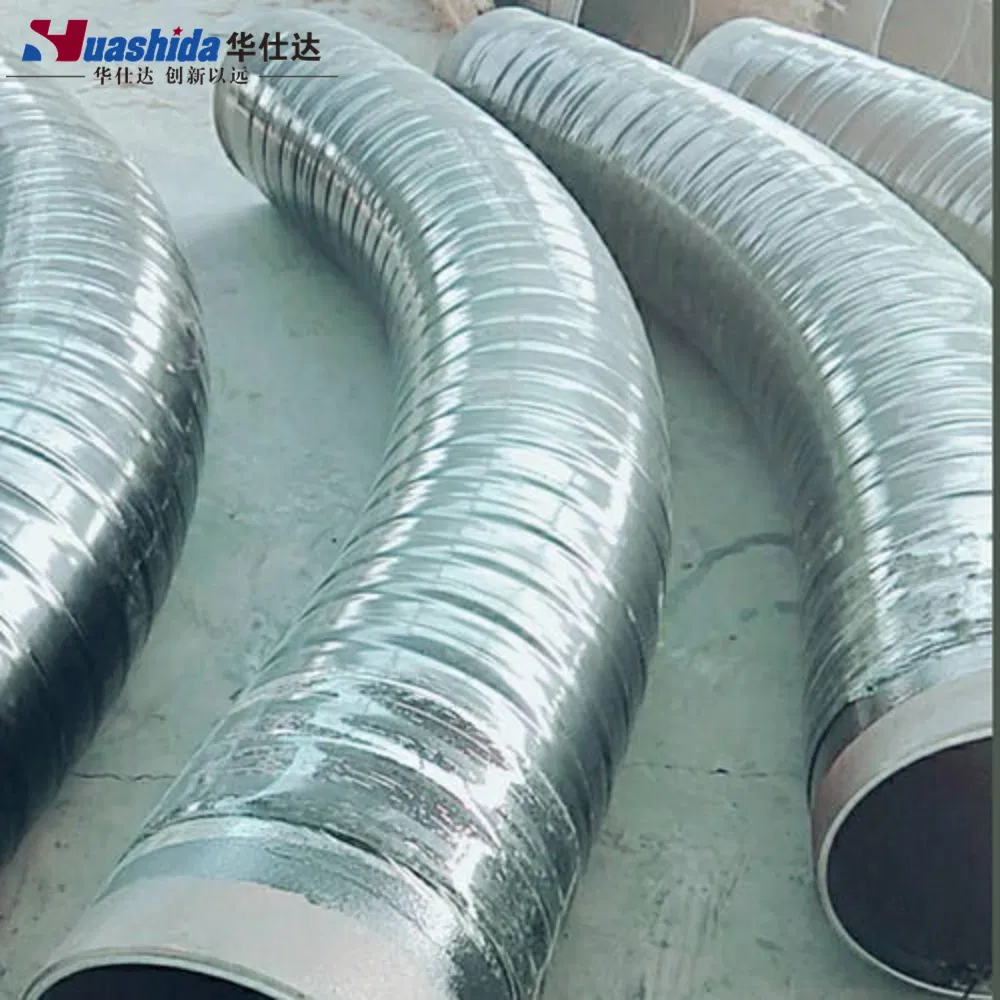

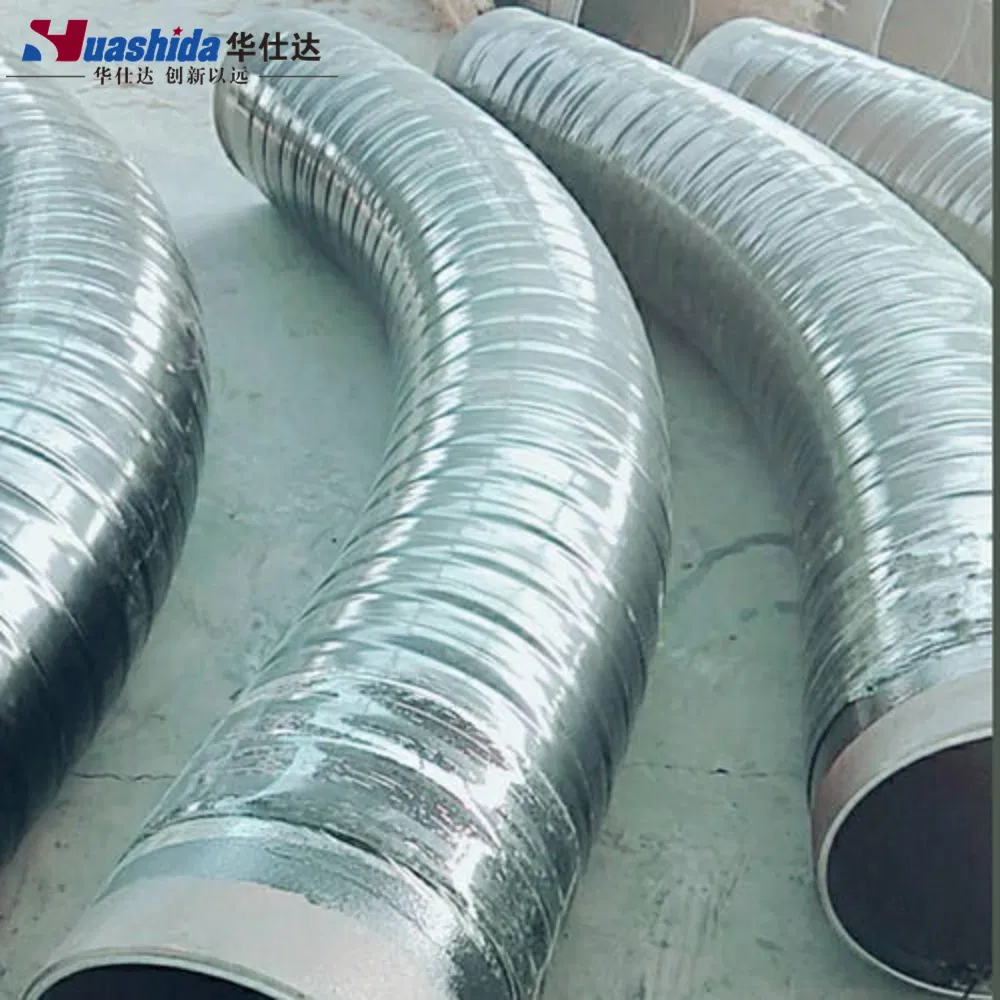

La línea de producción anticorrosión 3PE de codos de acero Qingdao Huashida se utiliza principalmente en diversos campos, como el transporte industrial de petróleo y gas, el transporte de suministro de agua, el transporte de aguas residuales y el transporte de productos químicos.

Se han instalado al menos dieciséis conjuntos de estructuras de transporte de tuberías de codo, con tuberías de codo colocadas en las estructuras de transporte. El eje giratorio del mecanismo de accionamiento es impulsado por un motor giratorio para hacer girar la placa de engranajes, y la potencia rotacional se transmite a través del mecanismo de accionamiento como centro. Ajuste la altura del rodillo de goma colgante utilizando el dispositivo de elevación de la estructura de transporte de tuberías de codo para adaptarse a la altura central uniforme de diferentes diámetros de tubería.

Características

1. Línea transportadora de tuberías de codo variable

Rompiendo el marco general de las líneas transportadoras convencionales, se ha diseñado una "línea transportadora de tuberías de codo variable" con un centro anticorrosión fijo para tuberías dobladas, lo que permite que tuberías con diferentes diámetros de codo, radios de curvatura y ángulos se sometan a operaciones anticorrosión en la misma línea de producción.

2. Tecnología precisa de determinación de arco

Se desarrolló una tecnología precisa de determinación de arco, utilizando cabezales de expansión de aleación para agrandar el diámetro de las tuberías de acero y eliminar la tensión interna durante la deformación por calentamiento. Posteriormente, se llevaron a cabo un enfriamiento rápido y un tratamiento de revenido para obtener tuberías curvas precisas, superando el problema de que los equipos CNC existentes no pueden manejar con precisión el retroceso elástico, el alargamiento y el radio de formación.

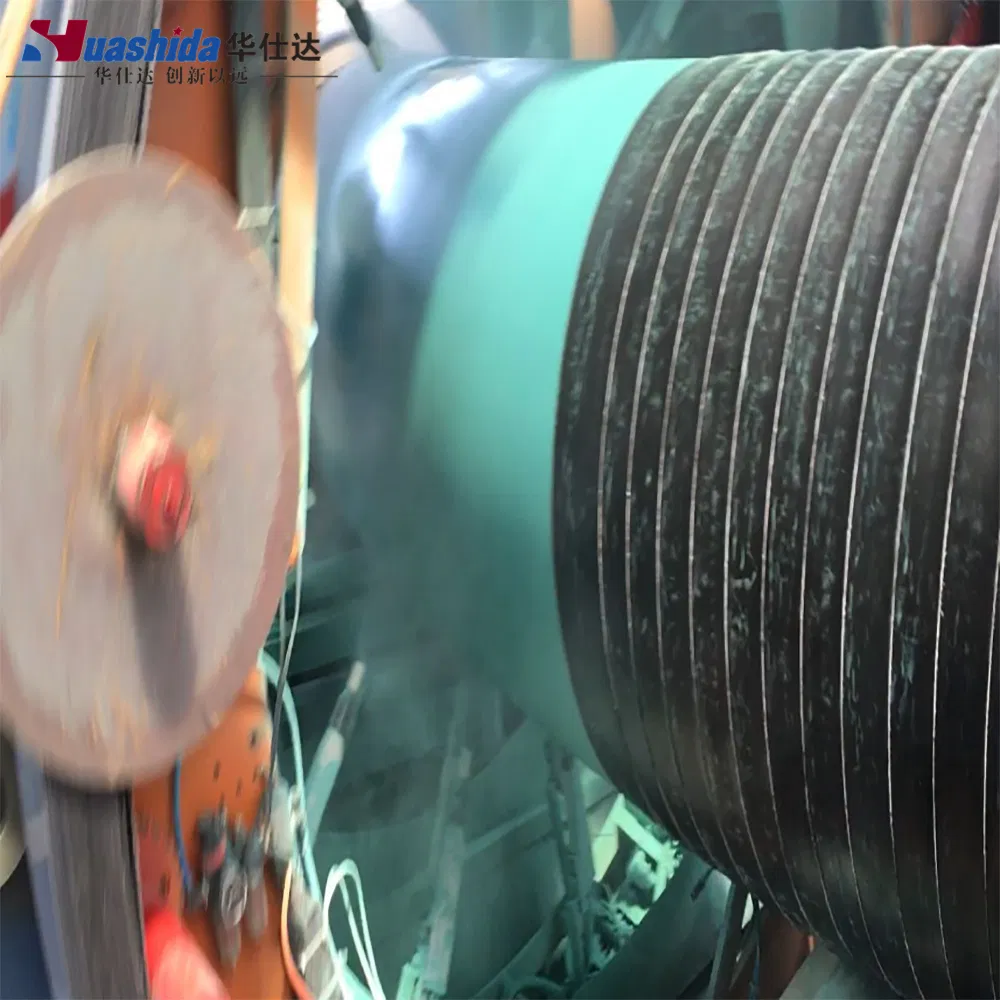

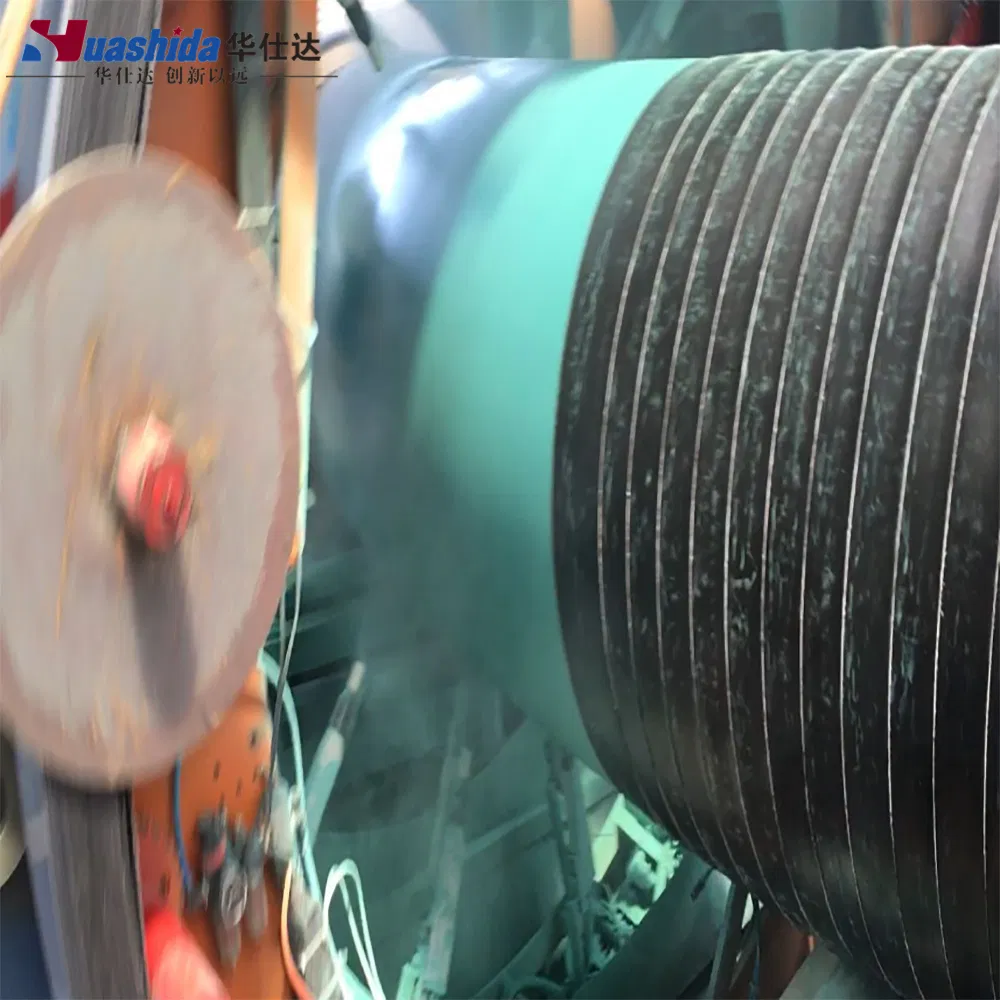

3. Dispositivo de bobinado coaxial para tuberías curvas

Se ha diseñado un dispositivo de bobinado coaxial para tuberías curvas, que adopta el principio asíncrono de los ejes interno y externo y la tecnología de diámetro de expansión y contracción interna para resolver el problema del bobinado con diferentes diámetros girando a la misma velocidad lineal, logrando un bobinado automático continuo y preciso.

4. Tecnología de recubrimiento por pulverización

Se desarrolló la tecnología de pulverización electrostática de alto voltaje externa para tuberías de codo para lograr el procesamiento automático de pulverización electrostática. Mejora eficazmente la uniformidad de la pulverización superficial en las tuberías de acero. El recubrimiento superficial es delgado, uniforme y tiene buen brillo. Al mismo tiempo, el recubrimiento tiene buena adherencia, alta dureza y buena resistencia a la corrosión.

5. Tecnología de ebullición de sulfuro

Se aplicó la tecnología de ebullición fluidizada para lograr el control automático del calentamiento y la fusión del polvo FBE. Fácil de operar, bajo consumo de energía y rendimiento físico estable.

Parámetros del producto

Parámetros de la tubería de revestimiento de codo 3lpe

| elemento |

Nombre |

especificación |

| 1 |

Diámetro de la tubería de acero |

426, 630, 720, 820,1000,1200 |

| 2 |

Radio de curvatura |

4-6 veces D |

| 3 |

Ángulo del codo |

15-90 grados |

| 4 |

Grosor de la pared del tubo de acero |

8 mm -12 mm |

| 5 |

Grosor del polvo epoxi |

más de 170 um |

| 6 |

Grosor del adhesivo de copolímero AD |

170-250 um |

| 7 |

Grosor de la capa de PE |

2.5 - 3.7 mm |

Nuestras ventajas

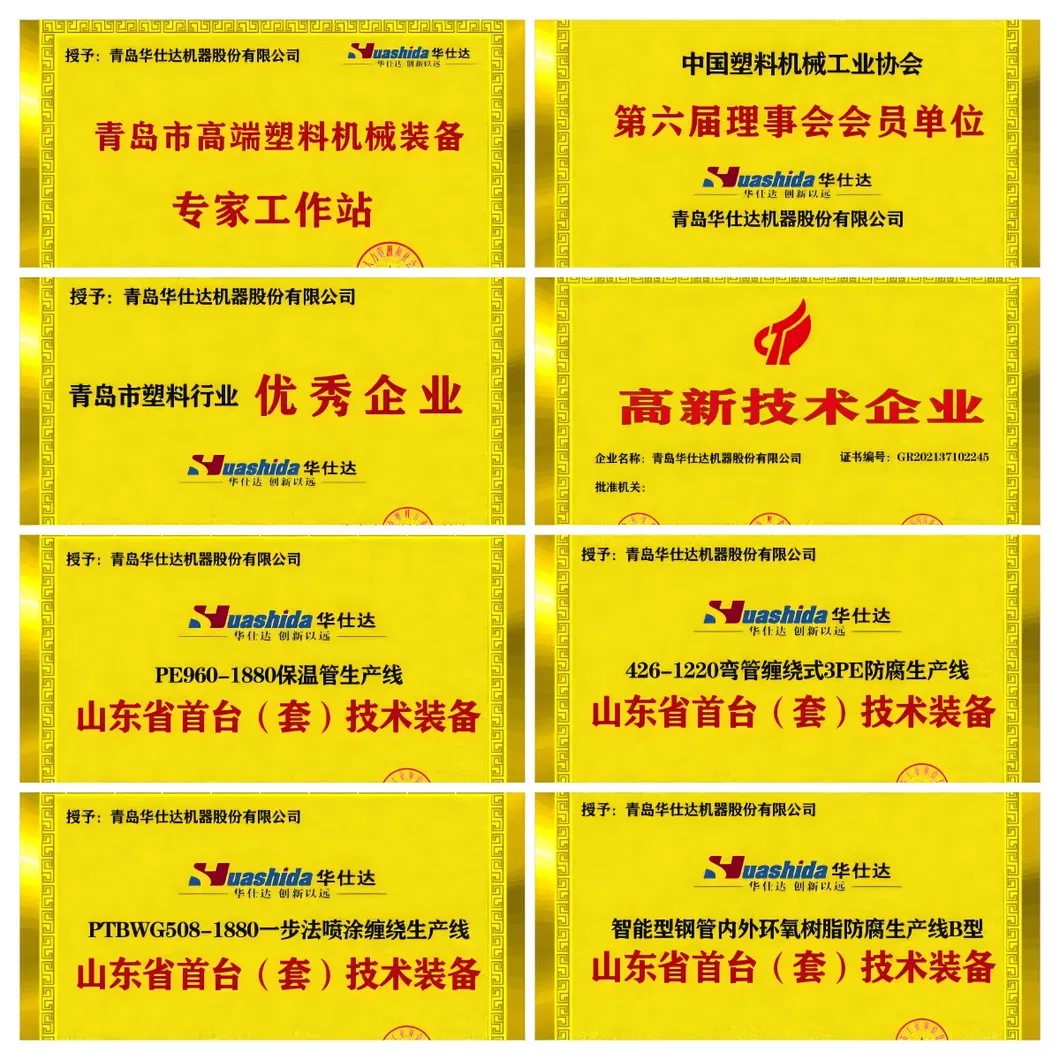

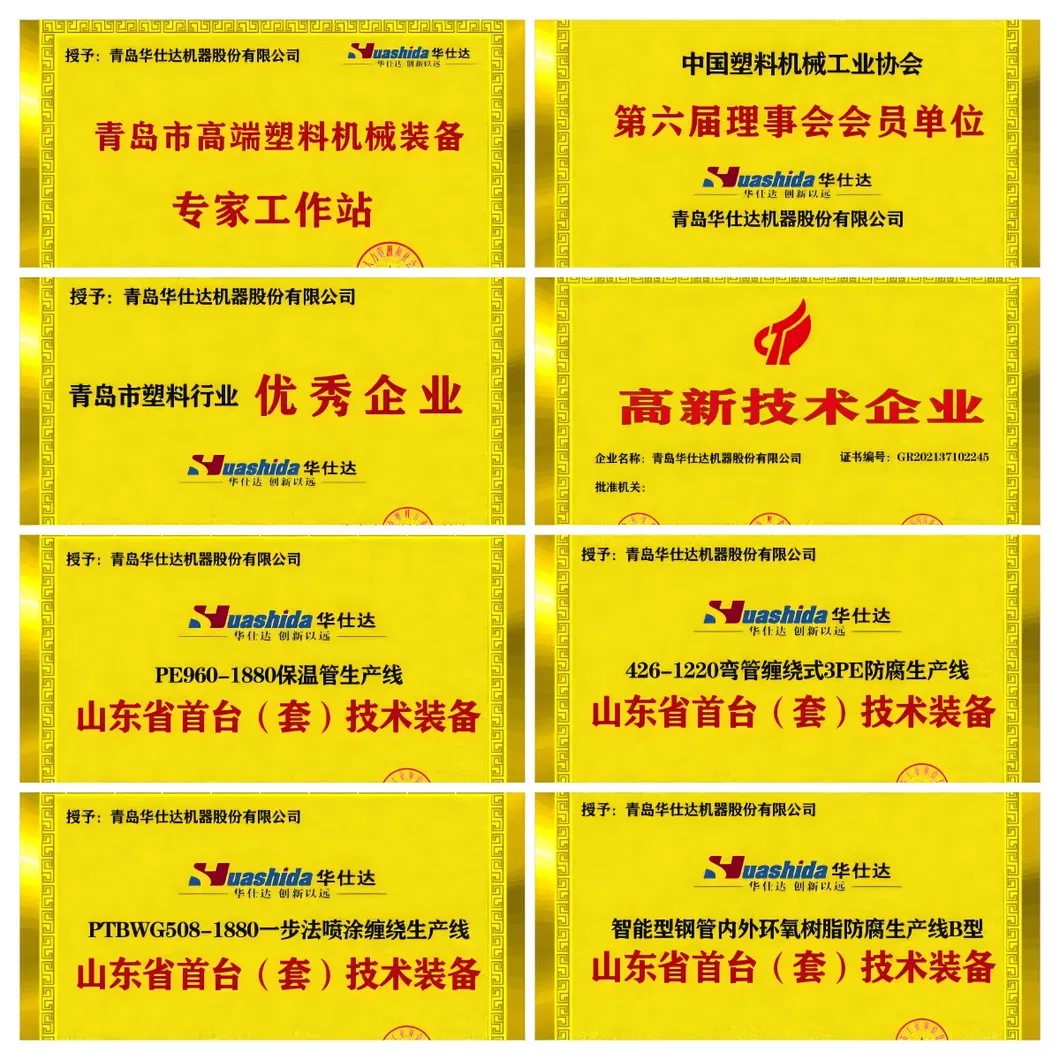

1. Galardonado con el primer (conjunto) equipo técnico en la provincia de Shandong

2. Más eficiente y estable

3. Alto grado de automatización, diseño inteligente, reduciendo la mano de obra manual

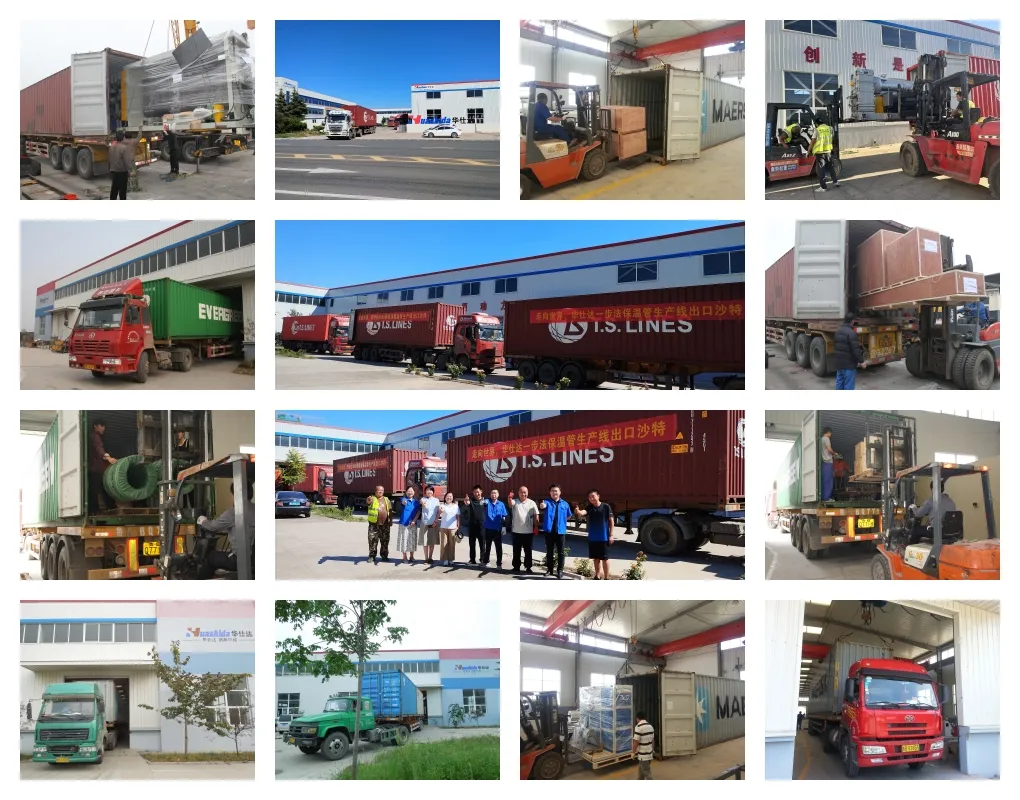

4. El 70% de los productos se envían a países y regiones como Europa, América, Oriente Medio, Asia Central, África, Rusia, etc.

5. Alta cuota de mercado

Qingdao Huashida Machinery Co., Ltd se estableció en 2003. Desde su inicio, Huashida se ha centrado en la línea de producción de tuberías de aislamiento de poliuretano plástico línea de producción de tuberías anticorrosión 3PE, línea de producción de tuberías subterráneas de gran diámetro y juntas de tuberías de plástico durante 20 años. Siempre concedemos gran importancia a la investigación y el desarrollo, colaborando estrechamente con la Universidad de Beijing detecnología química, la Universidad de tecnología de Qingdao y las instituciones de investigación científica. Al absorber tecnología avanzada en el país y en el extranjero, después de 20 años de esfuerzo, ahora nos clasificamos entre los 3 principales fabricantes de la industria en China. Las máquinas Huashida han sido bien recibidas en Arabia Saudita, Kazajstán, Uzbekistán, Emiratos Árabes Unidos, Turquía, Rusia, etc. Exposición

cliente

embalaje

Certificaciones

¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!  ¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!